In the process of printing, a distinction is made the two types of machines: sheet-fed and reel-fed machines. For this production we use the following printing methods:

All our printing technics are standardized, well worked-out and proven. This allows us to achieve high quality result.

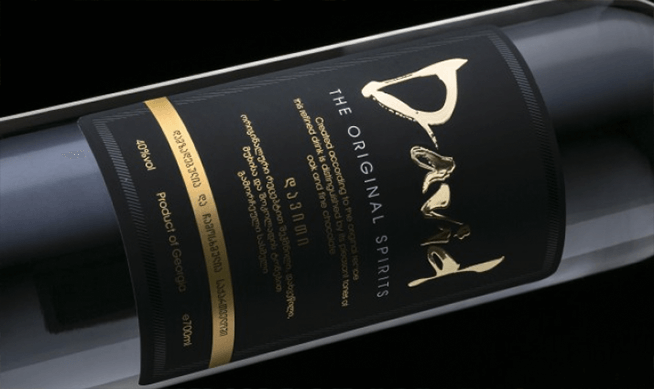

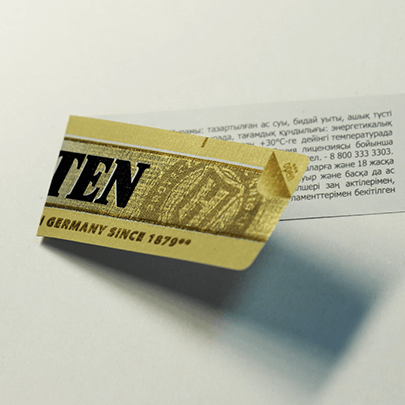

Foil stamping is a special kind of printing procedure where heat, pressure, and a metallic foil is used to create different shiny designs and graphics on various materials. Foil stamping gives the stamped design an incredible look and is increasingly becoming the preferred method of printing in many industries.

Our choice of color and foil texture is diverse, including foil with holograms, individually made to order.

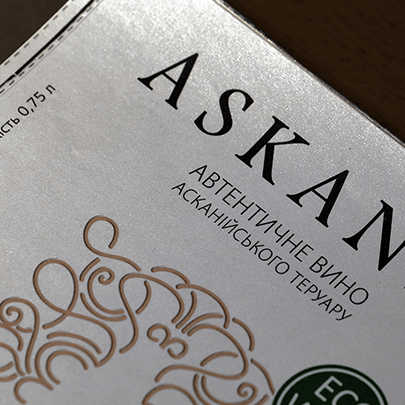

Embossing and debossing are the processes of creating either raised or recessed relief images and designs in paper and other materials.

It adds a subtle 3-dimensional effect to your product, as we can provide single-, double-, and multi-level voluming effect. Embossing technology can be combined with foiling for additional perks.

Laminating is the process whereby a special matte and glossy plastic film is bonded onto the surface of printed materials.

The main purpose of lamination is to protect products from external influences and mechanical damage. Laminated materials can withstand a lot of handling and can easily be wiped clean, last for a very long time and don’t lose relish, in this respect.

UV varnishing adds a striking effect on laminated paper, for high quality designs. UV varnishing provides the effect of:

Applied to a selected area (spot UV-varnishing) or to the entire print surface, UV varnishing adds longevity to your print media, protects the material from moisture and fingerprint contamination and prevents abrasion of ink layer, increases the strength and durability of the products.

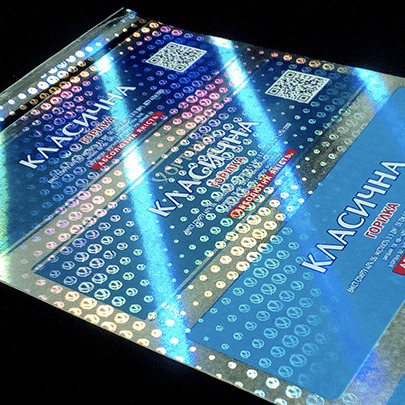

Holography takes a special place in the processes of varnishing and laminating.

In 2015, we have obtained the utility model patent for Holographic coating technology. This method does not only protect our customer from fraud, but makes the product attractive and eye-catching.

We offer a wide range of holographic films in order to implement various ideas and desires of our customers.

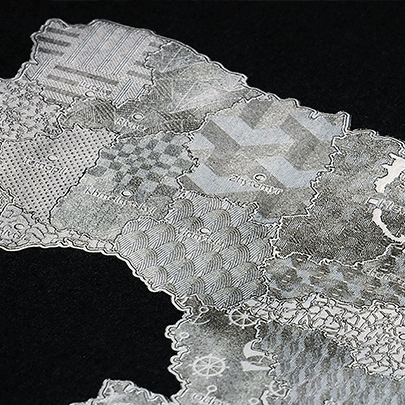

Microembossing is the latest technology of creating raised relief images and designs on smooth surface of paper, foil or soft cardboard.

In combination with UV-inks printing, micro embossing is being a unique alternative to textured paper and cardboard.

As a result, foil surface reflects light in different directions, creating additional visual effect.

In accordance with your needs and ideas, we can design and produce personal holograms, individually to your order.

Holographic imprints and images can include logo, text and graphic information. This technology is unique protection against fraud.

Volume foil stamping is our patented technology which can provide a special voluminal effect of the printing elements.

Special additives – glitters (different colors and fractions) mixed with UV-varnishes or inks, can create decorative effects of:

In addition to visual effects, glitters enables to create flavored images.

Peel-off labels are single-use labels for the containers, boxes, packing materials, bottles, tubes. Due to the special varnish on the back side, these labels are expandable and removable without damage.

Thus, we can apply any additional information as promo codes, translations, promotion details etc.

Luminous ink is versatile product and can be used for any element to glow in the dark, which adds elegance and attracts customers.

Thermochromic ink gives a well-defined color change at a certain temperature. It possess reversible effect and can be repeated many times.

Our manager will call you back